Workshop For Bop Recertification

Our Services

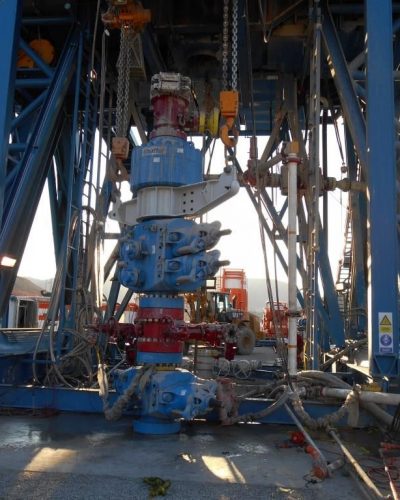

Workshop For Bop Recertification

Euro Tech can repair and recertification virtually any blowout preventer, valve, or choke manifold. All testing, inspections, welding, and machining are performed in-house or by approved third-party OEM. In addition, all repairs are performed according to API specifications. Document packages are also provided on request and include inspection

reports, NDE reports and test charts, as well as MTR’s when applicable.

Features:

- Vertical and horizontal boring

- Drilling/milling/threading

- Welding

- Buffing/polishing

- Dis assembly/inspection re-assembly

- Chrome plating

- All applicable testing and stress relief

Drilling Bop Servicing Sow

- Rig Down & Logistics

- Removal & Installation of temp. BOP

- BOP cleaning by means of washing and sandblasting

- Dimensional inspection & non destructive testing,

such as ultrasound, liquid penetration and magnetic particle inspection - Heat treatment to identify cracks and other faults

- Welding and machining of components to remanufacture elements of the BOP stack

- Re-assembly of full BOP stack

- Shell testing and functional testing

- Monitoring, recording of test performance & certification of BOP

- Skid mounted delivery to rig contract base